Welcome to “The Complete Guide to Troubleshooting and Maintenance of A/C Systems,” a comprehensive resource designed to help you effectively troubleshoot and maintain your A/C system. Whether you are a homeowner looking to save money by fixing common issues yourself or a professional in the HVAC industry seeking to enhance your skills, this guide covers all the key aspects of A/C system maintenance and troubleshooting. From identifying common problems to performing routine maintenance tasks, this guide will equip you with the knowledge and skills needed to keep your A/C system running smoothly and efficiently. Have you ever experienced issues with your A/C system and wondered how to troubleshoot and maintain it properly? This complete guide will provide you with the necessary information to keep your A/C system running smoothly and efficiently. From troubleshooting common problems to performing regular maintenance tasks, this guide will help you ensure your A/C system operates at its best.

This image is property of greenleafair.com.

Understanding Your A/C System

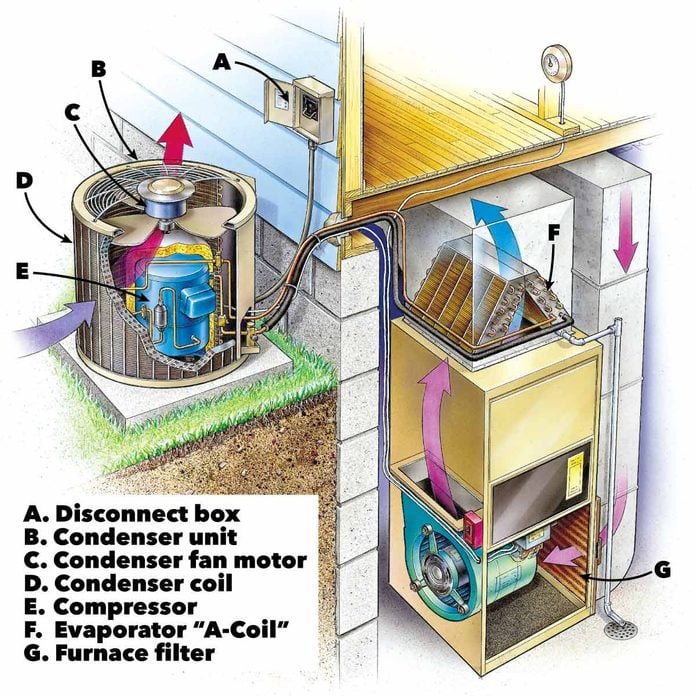

Understanding how your A/C system works is essential for troubleshooting and maintaining it effectively. The A/C system consists of several key components that work together to cool and circulate air throughout your home or vehicle. These components include the compressor, condenser, evaporator, expansion valve, and refrigerant. Familiarize yourself with these components to better understand how your A/C system functions.

Compressor

The compressor is a crucial component of the A/C system that pressurizes and circulates the refrigerant. It is responsible for compressing the low-pressure gas refrigerant into a high-pressure gas, which then flows to the condenser to release heat.

Condenser

The condenser receives the high-pressure gas refrigerant from the compressor and cools it down, causing it to condense into a high-pressure liquid. The condenser is typically located in front of the radiator in a vehicle or outside the home, where it can dissipate the heat absorbed from the refrigerant.

Evaporator

The evaporator is where the high-pressure liquid refrigerant expands and evaporates into a low-pressure gas. This process absorbs heat from the air passing through the evaporator coils, cooling the air before it is circulated back into the living space.

Expansion Valve

The expansion valve regulates the flow of refrigerant into the evaporator, controlling the temperature and pressure of the system. It ensures that the refrigerant evaporates and absorbs heat efficiently to provide cool air.

Refrigerant

Refrigerant is the chemical substance used in the A/C system to absorb and release heat as it cycles through the system. Common refrigerants used in A/C systems include R-22 and R-410A, with newer systems transitioning to more environmentally friendly alternatives.

Understanding how each component of your A/C system functions will help you identify potential issues when troubleshooting and perform maintenance tasks effectively.

Troubleshooting Common A/C Problems

A/C systems can experience various issues that affect their performance and efficiency. By understanding common problems and their causes, you can troubleshoot and address these issues promptly to prevent further damage to your A/C system.

No Airflow

If your A/C system is running, but there is little to no airflow coming out of the vents, several factors could be causing this issue. Start by checking the air filter, as a clogged or dirty filter can restrict airflow and reduce performance. Additionally, check for obstructions in the ductwork or vents that may be blocking the airflow.

Insufficient Cooling

If your A/C system is running, but the air coming out of the vents is not cold enough, the issue may lie with the refrigerant levels or the compressor. Low refrigerant levels can prevent the system from cooling effectively, while a faulty compressor may not be circulating the refrigerant properly.

Strange Noises

Unusual noises coming from your A/C system, such as banging, rattling, or squealing, could indicate mechanical issues with the compressor, fan, or other components. Inspect the system for loose or damaged parts that may be causing the noise and address them promptly to prevent further damage.

Leaking Water

Water leaks from the A/C system can be a sign of a clogged condensate drain or a refrigerant leak. Inspect the condensate drain for clogs and clear any blockages to allow proper drainage. If you suspect a refrigerant leak, contact a professional to repair the issue and recharge the system.

Thermostat Malfunction

The thermostat controls the temperature settings of your A/C system, and a malfunctioning thermostat can result in erratic cooling or heating. Check the thermostat settings and replace the batteries if needed. If the issue persists, consider replacing the thermostat to ensure accurate temperature control.

Electrical Issues

Electrical problems, such as blown fuses, tripped circuit breakers, or faulty wiring, can cause your A/C system to malfunction or stop working altogether. Inspect the electrical components of the system, including the wiring and connections, and replace any damaged parts to restore functionality.

By troubleshooting common A/C problems proactively, you can prevent minor issues from escalating into major repairs and ensure your A/C system operates efficiently.

This image is property of www.familyhandyman.com.

Performing Regular Maintenance Tasks

Regular maintenance is essential for keeping your A/C system in top condition and extending its lifespan. By following a maintenance schedule and performing routine tasks, you can optimize the performance of your A/C system and avoid costly repairs.

Changing the Air Filter

One of the simplest and most effective maintenance tasks for your A/C system is changing the air filter regularly. A dirty or clogged air filter can restrict airflow, reduce efficiency, and strain the system. Check the air filter monthly and replace it every 1-3 months, depending on usage.

Cleaning the Condenser and Evaporator Coils

Over time, the condenser and evaporator coils can accumulate dirt, dust, and debris, reducing the system’s efficiency. Inspect the coils annually and clean them with a soft brush or vacuum to remove any buildup. Ensure the coils are free of obstructions for optimal performance.

Checking Refrigerant Levels

Low refrigerant levels can impair the cooling capacity of your A/C system and lead to inefficiencies. Have a professional technician inspect the refrigerant levels annually and recharge the system if needed. Proper refrigerant levels are essential for effective cooling performance.

Inspecting Ductwork and Seals

Leaky ductwork and seals can result in energy loss and reduced cooling efficiency in your A/C system. Inspect the ductwork for signs of leaks, gaps, or damage, and seal any openings with duct tape or sealant. Properly sealed ducts will improve airflow and performance.

Lubricating Moving Parts

The moving parts of your A/C system, such as the fan motor and blower, require regular lubrication to reduce friction and wear. Check the manufacturer’s recommendations for lubrication intervals and apply lubricant to the moving parts as needed. Proper lubrication will ensure smooth operation and extend the lifespan of the components.

Testing Thermostat Accuracy

To ensure accurate temperature control and efficient cooling, test the accuracy of your thermostat periodically. Use a separate thermometer to compare the temperature readings with the thermostat settings and adjust as needed. Calibrate the thermostat if the readings are inaccurate to maintain consistent comfort levels.

Scheduling Professional Maintenance

In addition to performing routine maintenance tasks yourself, schedule annual professional maintenance for your A/C system. A qualified technician can inspect, clean, and tune up the system to ensure optimal performance and identify any potential issues early. Professional maintenance will prolong the lifespan of your A/C system and prevent costly repairs.

By following a regular maintenance schedule and performing essential tasks, you can keep your A/C system in peak condition and enjoy efficient cooling performance year-round.

This image is property of Amazon.com.

Conclusion

Maintaining and troubleshooting your A/C system is essential for ensuring its longevity and efficiency. By understanding how your A/C system works, identifying common problems, and performing regular maintenance tasks, you can keep your system running smoothly and avoid costly repairs. Remember to change the air filter regularly, clean the condenser and evaporator coils, check refrigerant levels, inspect ductwork and seals, lubricate moving parts, test thermostat accuracy, and schedule professional maintenance to keep your A/C system in top condition. With this complete guide, you’ll be well-equipped to troubleshoot and maintain your A/C system effectively.

This image is property of jmsmithhvac.com.