In order to ensure that your air conditioning system operates efficiently and can withstand the summer heat, conducting regular maintenance inspections is crucial. This comprehensive guide will walk you through the step-by-step process of performing a DIY A/C maintenance inspection, providing you with the necessary knowledge and techniques to not only identify potential issues but also prevent costly repairs. By devoting your attention to this essential task, you can prolong the lifespan of your A/C unit and enjoy uninterrupted comfort throughout the hot summer months.

Understanding the Basics of A/C Systems

Concept of air conditioning

Air conditioning, or A/C, is a system that regulates the temperature, humidity, and ventilation of an indoor environment. It works by extracting heat from the air inside a space and transferring it to the outside, leaving the indoor area cooler and more comfortable. A/C systems are commonly used in residential and commercial buildings to create a pleasant indoor environment during hot weather.

Components involved

A typical A/C system consists of several key components. The primary components include an outdoor condenser unit, an indoor air handler, ductwork, and a thermostat. The outdoor condenser unit houses the compressor and condenser coil, while the indoor air handler contains the blower, evaporator coil, and filter. The ductwork is responsible for distributing the conditioned air throughout the building. The thermostat is the control center that allows the user to set the desired temperature and control the operation of the A/C system.

How it works

The operation of an A/C system involves the circulation of refrigerant, a special chemical that can change between gas and liquid states at low temperatures. The refrigerant absorbs heat from the indoor air as it evaporates into a gas form in the evaporator coil, cooling down the air. The heated refrigerant gas is then compressed by the compressor in the outdoor unit, which raises its temperature. As the refrigerant flows through the condenser coil, it releases the absorbed heat to the outside air and condenses back into a liquid. The cycle repeats, maintaining the desired indoor temperature.

Identifying the Type of A/C

Central A/C

Central A/C systems are the most common type found in homes and large buildings. They consist of a centralized unit, usually located outside the building, that cools the air and distributes it through a network of ducts. Central A/C systems provide efficient and uniform cooling throughout the entire building, making them a popular choice for those seeking whole-house cooling solutions.

Ductless, mini-split A/C systems

Ductless, mini-split A/C systems are a great option for buildings where installing ductwork is not feasible or desired. These systems consist of an outdoor unit and one or more indoor units that are mounted on the wall or ceiling. They are connected by refrigerant lines, eliminating the need for ducts. Ductless systems offer flexibility in zoning, allowing different areas or rooms to be independently cooled, making them energy-efficient and customizable.

Window units

Window units are compact A/C systems designed to fit into a window opening. They consist of a self-contained unit that contains all the necessary components. Window units are typically used to cool individual rooms or small spaces. They are affordable, easy to install, and well-suited for small spaces or rental properties.

Portable units

Portable A/C units are similar to window units but offer the advantage of being mobile. They are self-contained systems that can be moved from room to room and do not require permanent installation. Portable units are a convenient cooling solution for areas without access to external windows or for those who need cooling flexibility.

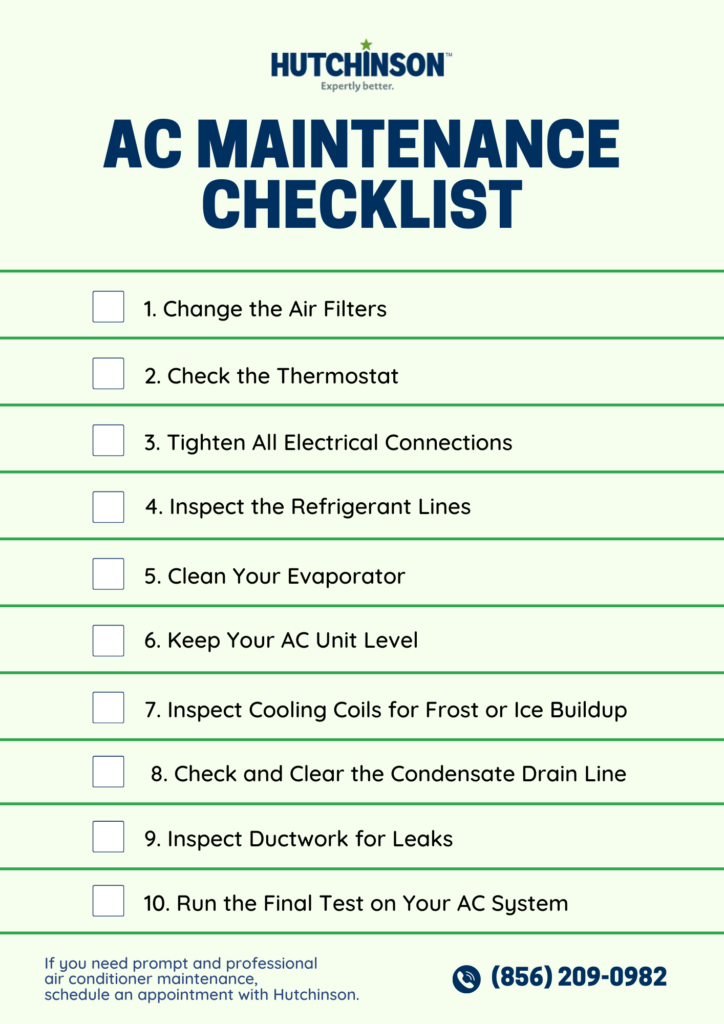

This image is property of www.hutchbiz.com.

Preparing for the Inspection

Turning off power supply

Before starting the A/C maintenance inspection, it is essential to turn off the power supply to ensure safety. Locate the electrical panel and turn off the corresponding circuit breaker or disconnect the A/C unit from the power source. This step prevents accidental electric shocks or injuries during the inspection process.

Gathering necessary tools

To perform a thorough A/C maintenance inspection, you will need a few tools. Some essential tools include a screwdriver, flashlight, cleaning brush, and a vacuum cleaner with a brush attachment. These tools will help you access and clean different components of the A/C system effectively.

Safety precautions

When performing any maintenance inspection on an A/C system, it is crucial to prioritize safety. Wear protective gloves and goggles to avoid any potential injuries. Make sure to work in a well-ventilated area, as some cleaning agents or debris may cause respiratory irritation. If you are unsure about any aspect of the inspection or feel uncomfortable with certain tasks, it is always best to seek professional assistance.

Checking the Thermostat

Ensuring proper working

Start the inspection by checking the thermostat. Ensure that it is powered on and functioning correctly. Check that the display is working properly and that the temperature settings can be adjusted. If the thermostat does not respond or display accurately, it may require troubleshooting or replacement.

Replacing batteries if necessary

If your thermostat operates on battery power, check the battery status and replace them with fresh ones if necessary. Weak or dead batteries can lead to malfunctions or inaccurate temperature readings, affecting the overall performance of the A/C system.

Confirming proper programming

Review the programming settings on the thermostat to ensure they align with your desired temperature preferences. Make any necessary adjustments to the schedule or temperature settings based on your comfort requirements. Confirm that the thermostat is set to the cooling mode during the warm weather season.

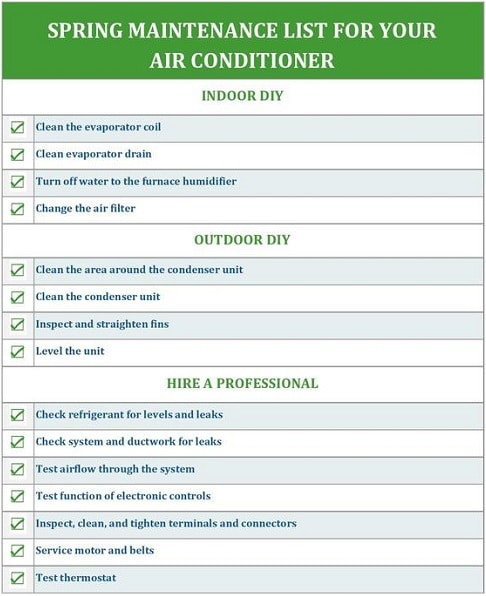

This image is property of static.houselogic.com.

Inspecting the Outdoor Condenser Unit

Checking for debris

Start by visually inspecting the outdoor condenser unit for any debris or obstructions. Remove any leaves, twigs, or other debris that may have accumulated around or inside the unit. Clearing away debris ensures efficient airflow and prevents clogs that could affect the A/C system’s performance.

Cleaning the unit

Use a soft brush or vacuum cleaner with a brush attachment to gently clean the condenser fins. Remove any dirt, dust, or debris that may have accumulated on the fins. It is essential to be cautious and avoid bending or damaging the delicate fins, as they facilitate heat exchange for effective cooling.

Looking for damage

Inspect the condenser unit for any signs of damage, such as bent fins, leaks, or loose connections. Bent fins can obstruct airflow, while leaks or loose connections can result in refrigerant leaks or inefficient cooling. If you notice any damage, it is advisable to contact a professional for repair or further inspection.

Evaluating the Air Filter

Locating the filter

Locate the air filter, which is typically located within the indoor air handler. Remove the cover or access panel to access the filter. Refer to the manufacturer’s instructions if you are unsure about the exact location of the filter in your specific A/C system.

Checking for dirt and clogs

Inspect the filter for dirt, dust, and debris accumulation. A dirty or clogged filter restricts airflow, reducing the A/C system’s efficiency and potentially causing strain on the blower motor. If the filter appears dirty or clogged, it is recommended to clean or replace it following the manufacturer’s guidelines.

Changing filter if necessary

If your air filter is disposable, replace it with a new one according to the recommended schedule. Disposable filters typically need to be replaced every 1-3 months, depending on usage and air quality. Follow the manufacturer’s instructions for the correct filter type and size.

This image is property of happyhiller.com.

Examining the Indoor Unit or Air Handler

Verifying blower function

Turn on the A/C system and verify that the blower is functioning correctly. The blower is responsible for circulating the cooled air throughout the building. Listen for any unusual sounds or vibrations that may indicate a problem with the blower motor. If you notice any issues, it is advisable to consult a professional for further inspection or repair.

Examining the evaporator coil

Inspect the evaporator coil inside the air handler for any signs of dirt or ice buildup. A dirty or frozen evaporator coil can impede heat exchange and reduce the efficiency of the A/C system. If you notice excessive dirt or ice, it is recommended to schedule professional cleaning or maintenance to ensure optimal performance.

Checking the drain pan and pipe

Inspect the drain pan located beneath the evaporator coil for any signs of water accumulation or leaks. A clogged or damaged drain pipe can cause water to back up and overflow, potentially leading to water damage or mold growth. Ensure that the drain pan and pipe are clear and functioning properly. If you encounter any issues, it is best to contact a professional for assistance.

Testing the Air Flow and Temperature

Measuring air flow from vents

Check the airflow from the A/C vents in different rooms or areas of the building. The airflow should be consistent and strong, indicating proper distribution of cooled air. If you notice weak airflow or uneven cooling, it may indicate a problem with the ductwork, blower, or other components of the system.

Comparing it with standard air flow

Consult the manufacturer’s specifications or guidelines to determine the recommended air flow rate for your specific A/C system. Compare the measured airflow with the standard guidelines to assess its efficiency. If the measured airflow falls significantly below the recommended range, it is advisable to seek professional inspection and servicing.

Verifying temperature matches with thermostat settings

Measure the temperature of the air coming out of the A/C vents and compare it with the thermostat setting. There should be a consistent and noticeable decrease in temperature as the air passes through the system. If the temperature does not match the thermostat setting or if there is no significant cooling effect, it may indicate a refrigerant leak or system malfunction, requiring professional evaluation.

This image is property of ushomefilter.com.

Maintenance of the Ductwork

Inspecting for leaks

Inspect the ductwork for any visible leaks or damaged sections. Leaky ducts can cause cooled air to escape before reaching the intended areas, resulting in reduced energy efficiency. Seal any visible leaks with appropriate duct tape or contact a professional for more extensive duct sealing if needed.

Checking for proper insulation

Check the quality and condition of the duct insulation. Properly insulated ductwork prevents temperature loss or gain during the air distribution process, maximizing energy efficiency. Replace or repair any damaged insulation to maintain optimal insulation performance.

Cleaning ducts if required

Consider scheduling professional duct cleaning if you notice excessive dirt, dust, or debris inside the ductwork or experience poor indoor air quality. Professional duct cleaning can help remove accumulated contaminants and improve the airflow and air quality in the building. Regular duct cleaning every few years can enhance the overall performance and lifespan of the A/C system.

Knowing When to Call a Professional

Issues beyond simple maintenance

While performing a DIY A/C maintenance inspection is beneficial for routine upkeep, some issues may require professional expertise. Complex repairs, electrical problems, or refrigerant leaks should be addressed by qualified technicians experienced in A/C system maintenance and repair.

System performance issues

If you observe consistent performance issues despite proper maintenance and inspection, it may indicate underlying problems that demand professional attention. Persistent issues such as inadequate cooling, frequent breakdowns, or unusual noises should be evaluated by an A/C technician to diagnose and rectify the problem effectively.

Signs of major component failures

Certain signs may indicate major component failures or impending system breakdown. These signs include unusual odors, smoke, erratic temperature fluctuations, or complete system failure. If you suspect any severe or hazardous issues with your A/C system, it is crucial to contact a professional immediately to prevent further damage and ensure the safety of your home or building.

In conclusion, performing a DIY A/C maintenance inspection is a proactive approach to ensure the efficient operation and longevity of your A/C system. By understanding the basics of A/C systems, identifying the type of A/C installed, preparing for the inspection, checking the thermostat, inspecting the outdoor condenser unit, evaluating the air filter, examining the indoor unit or air handler, testing the air flow and temperature, maintaining the ductwork, and knowing when to call a professional, you can effectively maintain and troubleshoot your A/C system. Regular maintenance and timely professional assistance will help keep your A/C system running smoothly, providing optimal comfort during hot weather seasons.

This image is property of edcprofessionalhomeinspections.com.