If you’re in the process of installing a mini-split AC system in your home, it’s essential to know how to properly size and install the refrigerant lines. Getting it right ensures optimal performance and efficiency for your cooling system. This article will guide you through the process, providing valuable tips and insights on sizing and installing your mini-split AC system’s refrigerant lines. Whether you’re a DIY enthusiast or hiring a professional, this information will help you make informed decisions and achieve the best results for your cooling needs.

Understanding Your Mini-Split AC System

Mini-split AC systems are a popular choice for cooling individual rooms or spaces in homes or commercial buildings. They are compact, energy-efficient, and offer customizable cooling options. Understanding how these systems work and their key components is essential for proper installation and maintenance.

Basics of Mini-Split AC Systems

A mini-split AC system consists of an outdoor unit and one or more indoor units connected by refrigerant lines. The outdoor unit houses the compressor and condenser, while the indoor units contain the evaporator coils and fans. This setup allows for cooling or heating of specific areas without the need for extensive ductwork.

Different Types of Mini-Split AC Systems

There are various types of mini-split AC systems available, each suited for different applications. Single-zone systems are designed to cool or heat one room, making them an ideal choice for bedrooms or offices. Multi-zone systems, on the other hand, can cool or heat multiple rooms or areas with the use of several indoor units connected to a single outdoor unit.

Key Parts of Mini-Split AC Systems

To properly understand and install your mini-split AC system, it’s important to familiarize yourself with its key components. The outdoor unit contains the compressor, condenser coil, and expansion valve. The indoor unit houses the evaporator coil, fan, and air filter. The refrigerant lines, which connect the outdoor and indoor units, are crucial for the system’s operation.

Properly Sizing Your Refrigerant Lines

Properly sizing your refrigerant lines is essential for the efficient operation and longevity of your mini-split AC system. It ensures that the refrigerant flows adequately between the outdoor and indoor units, allowing for optimum cooling or heating performance.

Role and Importance of Refrigerant Lines

Refrigerant lines play a crucial role in the functioning of your mini-split AC system. They carry the refrigerant from the outdoor unit to the indoor unit, where it absorbs heat from the room and releases it outside. Sizing the lines correctly ensures that the right amount of refrigerant is circulated, maximizing the system’s cooling capacity and preventing any issues with inadequate or excessive flow.

Key Factors to Consider When Sizing Refrigerant Lines

Several factors come into play when sizing refrigerant lines for your mini-split AC system. The length of the lines, the vertical rise or drop between the units, and the diameter of the lines all affect the system’s efficiency. Additionally, factors such as the operating temperature range, the distance from the outdoor unit to the farthest indoor unit, and the number of elbows or bends in the lines should be taken into account.

Common Mistakes to Avoid

When sizing refrigerant lines, it’s important to avoid common mistakes that can compromise the performance of your mini-split AC system. Oversizing or undersizing the lines can lead to inadequate cooling performance or increased energy consumption. It’s crucial to consult the manufacturer’s guidelines or seek professional assistance to ensure accurate line sizing.

Calculating the Required Size

Calculating the required size for your refrigerant lines involves understanding the BTU capacity of the system and the tonnage. This helps determine the appropriate line size that can efficiently handle the flow of refrigerant.

Understanding BTUs and Ton Capacity

British Thermal Units (BTUs) represent the amount of heat energy required to raise the temperature of one pound of water by one degree Fahrenheit. The ton capacity, on the other hand, refers to the cooling capacity of the system and is calculated based on a ton of ice melting in 24 hours. Understanding these units is essential for accurately sizing the refrigerant lines.

Methods of Calculating Required Line Size

There are various methods for calculating the required line size for your mini-split AC system. These methods include the longest line method, the manufacturer’s chart method, and the use of online calculators. Each method takes into consideration factors such as the length of the lines and the system’s BTU capacity to determine the appropriate line size.

Applying the Correct Formula

To calculate the required line size, you will typically need to know the BTU capacity of your system and the length of the refrigerant lines. Using the appropriate formula, which can be obtained from the manufacturer’s guidelines or online resources, you can determine the right size for your lines. It’s important to ensure that the lines are sized correctly to avoid any operational issues or system malfunctions.

Choosing the Right Type of Refrigerant Line

Choosing the right type of refrigerant line for your mini-split AC system is crucial for its overall performance and longevity. Different types of lines offer varying levels of insulation, durability, and flexibility.

Different Types of Refrigerant Lines

There are several types of refrigerant lines available in the market, including copper lines, copper-clad aluminum lines, and pre-insulated lines. Copper lines are widely used and are known for their durability and high heat conductivity. Copper-clad aluminum lines are a more cost-effective option, while pre-insulated lines offer ease of installation and added insulation.

Pros and Cons of Each Type

Copper lines offer excellent heat transfer capabilities and long-term reliability. However, they can be more expensive and require professional installation. Copper-clad aluminum lines are more affordable but may have lower heat conductivity. Pre-insulated lines are easy to install and provide insulation, but they may have limitations in terms of length and flexibility. Considering the pros and cons of each type is important when making your choice.

Making the Right Choice for Your System

When selecting the type of refrigerant line for your mini-split AC system, consider factors such as your budget, installation requirements, and performance expectations. Consulting with a professional or referring to the manufacturer’s recommendations can help you make an informed decision.

Purchasing Your Refrigerant Lines

Once you have determined the correct size and type of refrigerant lines for your mini-split AC system, it’s time to purchase them. Shopping for refrigerant lines involves finding a reliable supplier and considering factors such as quality, availability, and warranty.

Where to Buy

Refrigerant lines can be purchased from various sources, including HVAC supply stores, home improvement retailers, and online marketplaces. Research local suppliers or browse trusted online platforms to find reputable sellers with a wide selection of quality products.

What to Look for

When purchasing refrigerant lines, look for reputable brands known for their durability and performance. Consider the specific requirements of your system, such as line diameter and insulation thickness, to ensure a proper fit. Additionally, check for any warranty or guarantee offered by the manufacturer to protect your investment.

Top Brands and Products

Some well-known brands in the HVAC industry that offer quality refrigerant lines include Daikin, Mitsubishi, and Fujitsu. These brands are known for their reliable products and have a wide range of options suitable for different mini-split AC systems. Researching specific product models and customer reviews can help you make an informed decision when purchasing your refrigerant lines.

Preparing for Installation

Before installing the refrigerant lines for your mini-split AC system, it’s important to prepare adequately. This involves gathering the necessary tools, setting up a suitable work area, and taking necessary safety precautions.

Checklist of Required Tools

To ensure a smooth installation process, gather the necessary tools beforehand. Some common tools you may need include a pipe cutter, flaring tool, torque wrench, vacuum pump, and refrigerant gauges. Check the manufacturer’s guidelines for any specific tools recommended for your system.

Setting Up Your Work Area

Create a clean and organized work area that allows you to easily access all components and tools. Clear any obstacles or debris that may hinder the installation process. Additionally, ensure proper ventilation in the work area to prevent the buildup of refrigerant gases or fumes.

Safety Precautions to Take

Prioritize safety when installing your mini-split AC system’s refrigerant lines. Always wear appropriate protective gear, including gloves and safety glasses, to prevent any injuries. Familiarize yourself with the safety guidelines and procedures outlined by the manufacturer, and exercise caution when handling refrigerant or working with electrical components.

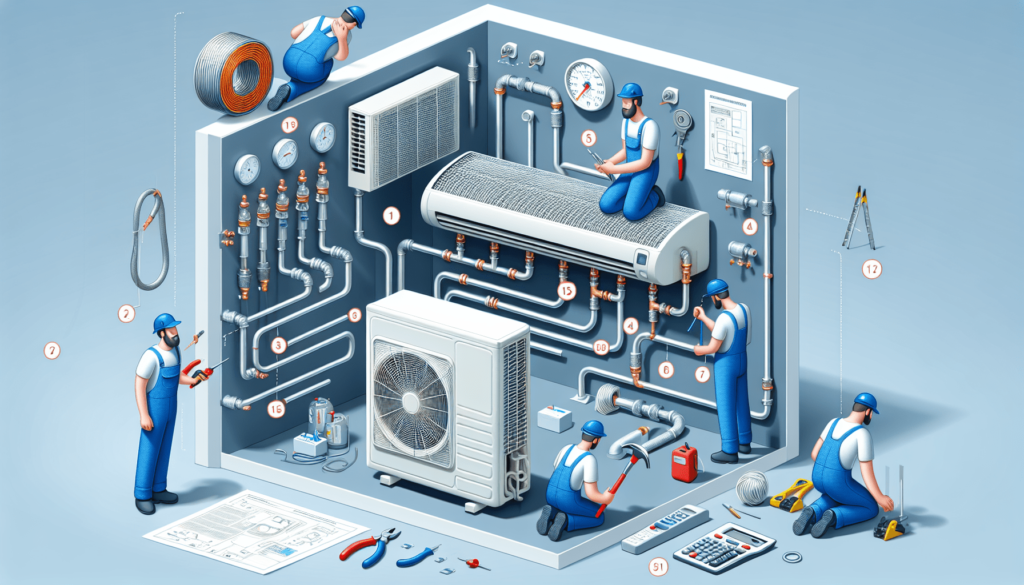

Step-by-Step Installation Process

Installing refrigerant lines for your mini-split AC system may seem complex, but following a step-by-step process can simplify the task. It’s important to work methodically and accurately to ensure a successful installation.

Marking and Cutting the Lines

Start by measuring and marking the refrigerant lines according to the manufacturer’s specifications. Ensure accurate measurements and use a pipe cutter or similar tool to cut the lines to the appropriate lengths. Take care to make clean, square cuts to ensure proper connections later on.

Securing the Lines

Once the lines are cut, secure them in place using appropriate fittings and clamps. This prevents any movement or vibration that may lead to leaks or damage. Use the manufacturer’s recommended methods for securing the lines, and ensure that all connections are tight and properly aligned.

Connecting the Lines to the System

After securing the lines, connect them to the outdoor and indoor units of your mini-split AC system. Follow the manufacturer’s instructions for the specific connections required. It’s important to ensure a proper seal and use any necessary insulation or tape to prevent any refrigerant leaks.

Checking Installation Quality

After completing the installation of your mini-split AC system’s refrigerant lines, it’s crucial to thoroughly inspect the work to ensure a high-quality installation.

Common Issues to Look For

Inspect the refrigerant lines for any signs of damage or improper installation. Look for kinks, bends, or dents that may restrict the flow of refrigerant. Check that all connections are secure and free from leaks. Additionally, verify that the lines are properly insulated to prevent any heat gain or loss.

Signs of Proper Installation

A properly installed system should have refrigerant lines that are properly sized, securely connected, and free from leaks. There should be adequate insulation on the lines to ensure optimal performance. The lines should also be properly supported and protected from any potential damage.

Using Refrigerant Line Leak Detectors

To ensure the integrity of your refrigerant lines, consider using a refrigerant line leak detector. This tool can help identify any refrigerant leaks in the system, allowing for prompt repairs and preventing any loss of cooling or heating efficiency. Follow the manufacturer’s instructions for the proper use of the leak detector.

Maintaining Your Refrigerant Lines

Regular maintenance of your mini-split AC system’s refrigerant lines is essential for optimal performance and longevity. This involves regular inspections, cleaning, and addressing any common issues that may arise.

Regular Inspections

Periodically inspect your refrigerant lines for any signs of wear, damage, or blockages. Look for any visible leaks, dents, or other issues that may impact the system’s performance. Additionally, check the insulation on the lines to ensure it is intact and free from any degradation.

Cleaning Your Lines

Cleaning the refrigerant lines helps maintain their efficiency and prevent any buildup of dirt or debris. Use a soft brush or cloth to remove any dust or grime from the lines. Avoid using harsh chemicals or abrasive materials that may damage the lines or insulation.

Addressing Common Issues

If you encounter any issues with your mini-split AC system’s refrigerant lines, it’s important to address them promptly. Common issues may include leaks, loose connections, or insulation damage. Consult the manufacturer’s guidelines or seek professional assistance to properly resolve any issues and prevent further damage to the system.

Common Mistakes to Avoid

When sizing and installing your mini-split AC system’s refrigerant lines, it’s crucial to avoid common mistakes that can compromise the system’s performance and lifespan.

Ignoring Manufacturer’s Instructions

Manufacturers provide specific guidelines and recommendations for properly sizing and installing refrigerant lines. Ignoring these instructions can lead to incorrect line sizing, inadequate performance, or even system failures. Always refer to the manufacturer’s guidelines and seek professional assistance if needed.

Incorrect Line Sizing

Properly sizing the refrigerant lines is crucial for the efficient operation of your mini-split AC system. Oversizing or undersizing the lines can lead to reduced cooling or heating capacity, increased energy consumption, and potential damage to the system. Consult the manufacturer’s guidelines or seek professional assistance to ensure accurate line sizing.

Improper Installation

Improper installation of the refrigerant lines can result in leaks, reduced performance, or even system damage. It’s important to follow the manufacturer’s instructions and best practices for installation. If you are unsure or inexperienced, consider hiring a professional HVAC technician to handle the installation and ensure it is done correctly.

By understanding your mini-split AC system and properly sizing and installing the refrigerant lines, you can ensure optimal performance, energy efficiency, and longevity. Taking the time to research, plan, and follow the manufacturer’s guidelines will help you achieve a successful installation and enjoy the benefits of reliable cooling or heating in your home or commercial space.